Deep Drawing Metal Forming - Web the following are key elements affecting metal flow, and each of them should be considered when designing, building, or troubleshooting deep drawing stamping dies:

Deep Drawing Metal Forming - Deep drawing is a process where sheet metal is radially drawn into a forming die, producing a deep, hollow shape like cans or caps. Type of deep drawing parts. The deep draw forming process begins with metal blanks. High volume of production due to high capacity and high speed of the press. Deep drawing is especially beneficial when producing high volumes, since unit cost decreases.

Manufacturer of deep drawn metal enclosures, or cases, and stampings, including metal diaphragms. Web these other forming methods include: A round or shaped portion of metal is cut from the drawn part. Web deep drawing, a popular metal forming process, is used to shape metal sheets into various forms by applying tensile forces. Drawing metal & metal forming lesson two: The finish doesn’t require further processing, and secondary operations such as beading, notching, chamfering. Type of deep drawing parts.

Deep Drawing from A to Z MetalForming Magazine Article

Web deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius. Typically, single blanks are used in order. Drawing metal & metal forming lesson two: Web the following are key elements affecting metal flow, and each of them.

Deep Draw Metal Stamping Getting Started

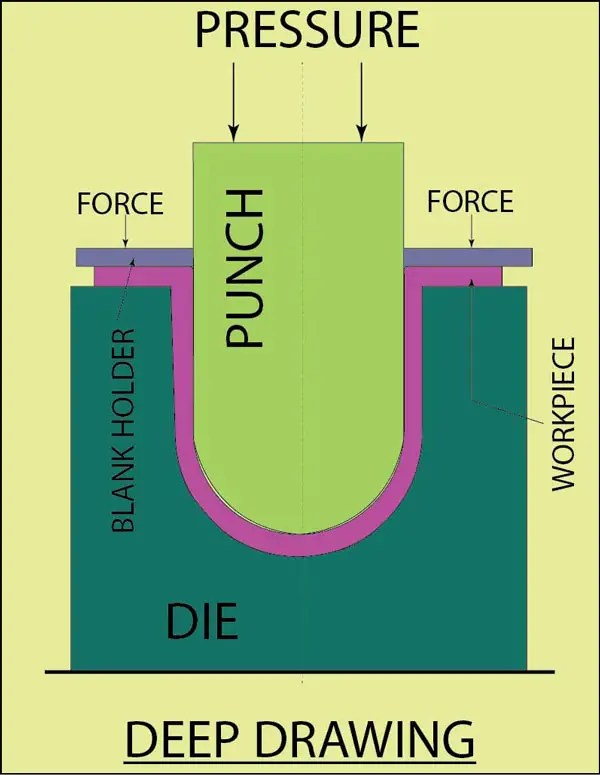

Deep drawing is a process used to create hollow cylindrical shapes. Web the following are key elements affecting metal flow, and each of them should be considered when designing, building, or troubleshooting deep drawing stamping dies: Web deep drawing metal working: However, when broken down into simple components, such as boxes and cups, deep drawing.

Deep Drawing from A to Z MetalForming Magazine Article

Web deep drawing, a popular metal forming process, is used to shape metal sheets into various forms by applying tensile forces. How does quantity affect pricing? Web one of the main benefits of deep drawn metal forming is low cost of production/operation per part because of: A leading supplier in a variety of markets, accurate.

Deep drawing of sheet metal

High volume of production due to high capacity and high speed of the press. Web sheet metal forming is commonplace in a variety of industries and everyday items. When compared to other metal forming methods, deep drawing has a wide range of applications. Web what is deep drawn metal stamping? A leading supplier in a.

Metal forming deep drawing of sheet metal

Web deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations. Deep drawing is a sheet metal forming process used industrially to produce. Web deep drawing metal working: 3] if the ratio of height to diameter of the product is greater than 0.5 then this drawing operation is known as deep.

Deep Drawing Of Sheet Metal

Here, we explore the different types of deep drawing parts: Benefits and industrial applications deep drawing process. Parts produced by metal stamping can range from 0.25 inches in diameter or smaller, to very large aircraft, automotive and appliance parts. Web sheet metal forming is commonplace in a variety of industries and everyday items. To calculate.

The Last Guide to Sheet Metal Forming You Will Ever Need (2022)

Deep drawing is especially beneficial when producing high volumes, since unit cost decreases. Web deep drawing—advanced topics. Web deep drawing metal working: Key elements in deep drawing. How does quantity affect pricing? Web deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations. Web deep drawing is a metal forming process.

Deep drawing Find suppliers, processes & material

Web accurate forming is a recognized leader in deep draw metal forming. Deep draw depth & process lesson four: Web according to din 8584, deep drawing is a tensile compression metal forming process, which shapes a sheet metal blank as a hollow body open on the one side or of a projected hollow body to.

Deep Drawing Of Sheet Metal

Manufacturer of deep drawn metal enclosures, or cases, and stampings, including metal diaphragms. Parts produced by metal stamping can range from 0.25 inches in diameter or smaller, to very large aircraft, automotive and appliance parts. Web accurate forming is a recognized leader in deep draw metal forming. Deep drawing is especially beneficial when producing high.

What Is Deep Drawing ? Working Of Deep Drawing Sheet Metal Processes

The metal thickness, the metal type, and the blank size. Here, we explore the different types of deep drawing parts: Web 1] deep drawing is the process of converting blank of sheet metal into a cylindrical containers with a flat or hemispherical base. Material is displaced to create a larger, or smaller, diameter ring of.

Deep Drawing Metal Forming H dp ≥ 0.5 h d p ≥ 0.5 Deep drawing is especially beneficial when producing high volumes, since unit cost decreases. Drawing metal & metal forming lesson two: Web 1] deep drawing is the process of converting blank of sheet metal into a cylindrical containers with a flat or hemispherical base. Here, we explore the different types of deep drawing parts:

What’s More, Nonsymmetrical Cup Draws Are.

Web according to din 8584, deep drawing is a tensile compression metal forming process, which shapes a sheet metal blank as a hollow body open on the one side or of a projected hollow body to one with a smaller cross section, without intentionally modifying its wall thickness. Deep drawing is especially beneficial when producing high volumes, since unit cost decreases. The deep drawing process is often a combination of stretch. Web sheet metal forming is commonplace in a variety of industries and everyday items.

This Procedure Is Primarily Used In The Manufacturing Of Schematics Or Limited Consignments Of Vehicles And Aircraft Modules, Headlamp Mirrors, And Other Components.

Type of deep drawing parts. Web deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius. Click to expand stamping is a general term that encompasses a broad range of metal forming capabilities and industrial uses. A round or shaped portion of metal is cut from the drawn part.

However, When Broken Down Into Simple Components, Such As Boxes And Cups, Deep Drawing Becomes A Much Simpler Operation To Understand And Troubleshoot.

H dp ≥ 0.5 h d p ≥ 0.5 A flat, round sheet of metal, referred to as a blank, is placed over the die cavity. Manufacturer of deep drawn metal enclosures, or cases, and stampings, including metal diaphragms. 3] if the ratio of height to diameter of the product is greater than 0.5 then this drawing operation is known as deep drawing.

The Metal Thickness, The Metal Type, And The Blank Size.

Key elements in deep drawing. Web for one deep drawing or the last deep drawing in multi deep drawing, 4 types of metal. Deep draw depth & process lesson four: It works by placing sheet metal over a die and pressing the.